Jones Engineering believe productivity and innovation need to be a huge focus in making the Irish construction industry the most productive, highest quality, safest and competitive in Europe and beyond.

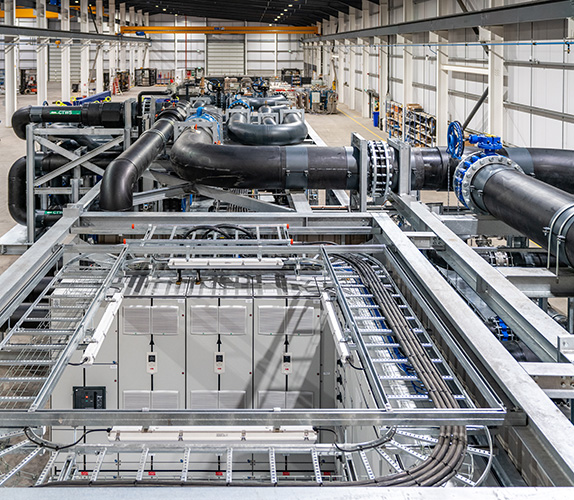

One of the ways Jones Engineering has been improving productivity is with the movement of the construction process away from the physical site into controlled manufacturing and assembly environments by providing integrated modular and off-site construction solutions.

With the backdrop of increasing demand for Life Science, Data Centre and Microelectronic manufacturing campuses – the timescale between Basis of Design (BOD) to Facility Ready (FR) has been under increasing pressure to reduce.

Jones Engineering

Jones Engineering, in an effort to increase efficiency and predictability, improve safety, minimise the level of disruption to site, client and the environment, and reduce the time frame of BOD to FR, have invested heavily in the past number of years in not just leaner ways of working but in challenging how the Engineering and Construction sector approaches the delivery of projects. These efforts culminated in the launch of a new division, Jones Engineering Manufacturing Ltd., in 2019.

Jones Engineering Manufacturing is based in a 9,000m2 centre of Design for Manufacturing & Assembly (DfMA) excellence in Co. Carlow. This stateof- the-art facility brings their core competencies in Mechanical, Electrical & Instrumentation and Fire Protection and the added competencies of Civil, Structural & Architectural under one roof. This allows their teams to design, manufacture, install and deliver modules from small to large-scale projects.

Their multidiscipline team, having a core understanding of traditional stick-build construction, have delivered on several “Integrated Modular Solutions” (Products) for clients based on the simple idea of “plug and play”; whereby they have taken a Client BOD to fully tested and commissioned CE / UKCA Marked products ready for site infrastructure integration.

The journey from BOD to CE /UKCA Marked Product progresses in parallel with the Client and A/E (Architectural / Engineering) Teams, striving for the design to be 100% complete prior to any physical manufacture or assembly. This ensures the end product is fit for purpose with the end user (Operations) always in mind. This collaborative and open approach has allowed Jones Engineering to transform how it delivers on projects providing for; improved design compliance, improved quality control, upfront efficient design processes and reduced manufacturing, assembly, integration (site) and operational risks. This results in improved predictable costs and allows for off-site commissioning and testing along the way while focussing on the speed of delivery of the overall project.

Fast-track modular design

Using fast-track modular design processes also takes a large percentage of the project work off-site, which improves site congestion. Reducing the number of people on site at any one time increases the safety of everyone. It is possible to provide clients with “Speed for Delivery” while prioritising safety by developing these types of innovative solutions.

“The off-site modular sector is key to the much-needed future development, innovation and success of the Construction Industry.

“A greater collaborative focus is required to increase efficiency & predictability, improve safety, along with minimising the level of disruption to site, client & the environment. We believe that all parties need to recognise the need to embrace change and, indeed, become agents for change within the Construction Industry. New mindsets, methods of engagement and relationship types must be explored and put in place without delay as the construction industry continues to move from a hierarchy approach to a more efficient and effective round table approach.

“Our experienced construction-manufacturing team bring this much-needed change towards a more efficient process for our customers; allowing them to maximise the potential of their project under one roof from Concept Design through to Off-Site Manufacture/Assembly and Site Integration. We currently design and manufacture for clients in Ireland, across mainland Europe and the UK,” says Ian Davy, General Manager, Jones Engineering Manufacturing.

This solution has been working well for their current clients. They have successfully transported cooling modules to Holland, Belgium, Finland, and Denmark, as well as E-Houses and Packaged Plant Rooms across Ireland and the UK. The average size of each component was 19m long by 4.2m wide by 4m high. This necessitated detailed planning and cooperation between the Jones logistics teams and the authorities involved, including permit applications etc. It has proved so successful they will be extending this solution on additional global sites in the future.

Building Information Modelling

Building Information Modelling (BIM) / Digital engineering is also critical to prefabrication and modular construction. It enables integrated architecture and engineering workflows. It supports the concept of repeatable designs, which enables optimisation of a design across the feasibility study and conceptual engineering.

Jones have been leading the way in BIM for over 15 years now and have recently obtained the BSI Kitemark™ for BS EN ISO 19650 parts 1 and 2. They successfully passed the audit held in 2021, making them the first Irish engineering contractor to hold a BSI Kitemark for BIM (Design and Construction) certificate against ISO 19650 that covers Mechanical, Electrical and Fire Protection systems. It demonstrates that Jones BIM processes, procedures, and management systems on completed projects are fully in compliance with international standards for managing information using BIM.

Jones credit these BIM achievements to the fact they constantly evaluate different software versions, system applications and advancements in construction methods in order to offer the best and most optimum solutions to deliver specific projects based on clients’ requirements. The Jones BIM Team utilise the latest BIM modelling techniques incorporating new self-established BIM initiatives to overcome previous challenges successfully. Unrivalled subject experts with a proven track record, Jones Engineering BIM apply specific design solutions and value engineering based on project scope, relevant challenges and exact end-user requirements, ensuring a risk-free programme for both the client and design team.

Some of their BIM projects in Ireland include Boland’s Quay, the EXO Building and the National Rehab Hospital. Overseas clients include confidential data centres, Bioenergy facilities and blue-chip pharmaceutical companies. Over the last five years, Jones Engineering teams have successfully completed almost €3billion worth of projects ranging from the Medical, Life Science, Building Services, Industrial, Semi-Conductor, Data Centre and Power and Energy Sectors, almost half of which was overseas.

Careers at Jones Engineering

Jones Engineering currently employs over 4,000 people working throughout Ireland, Europe and the Middle East. They have an annual training budget of over €2m and encourage all of their employees to attend internal and external training courses on a regular basis. Jones Engineering projects are based around the globe, giving employees the chance to work in extreme locations from Arctic conditions reaching sub-zero temperatures of -40° to extreme heat environments reaching temperatures of +50°. From offshore oil rigs prone to 100 mph winds and 80-foot wave surges to tunnelling under rivers and cities. The possibilities are limitless.

A list of current vacancies can be viewed on their website www.joneseng.com